Eventuri Honda V2 – Intake System with Upgraded Carbon/Kevlar Tube (Civic Fk2 Type R) – EVE-FK2V2-INT

HONDA CIVIC FK2 TYPE R V2

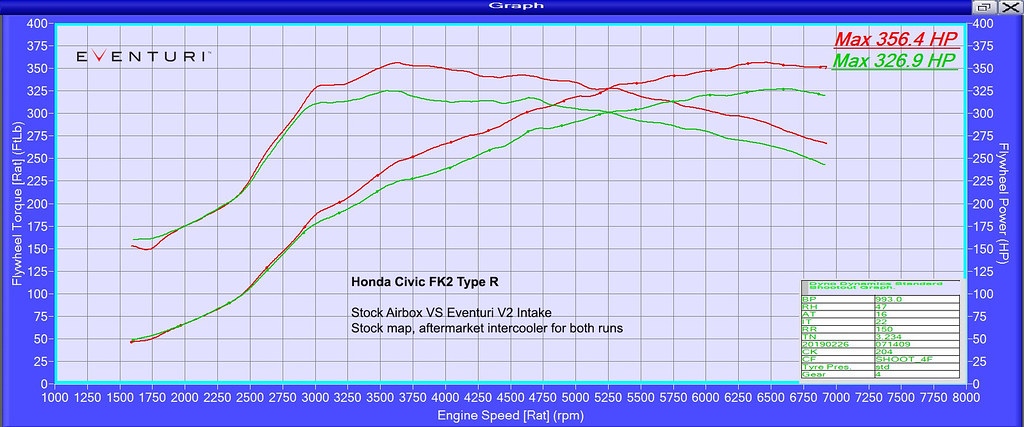

Performance Increase : 24-30hp, 28-35ft-lb

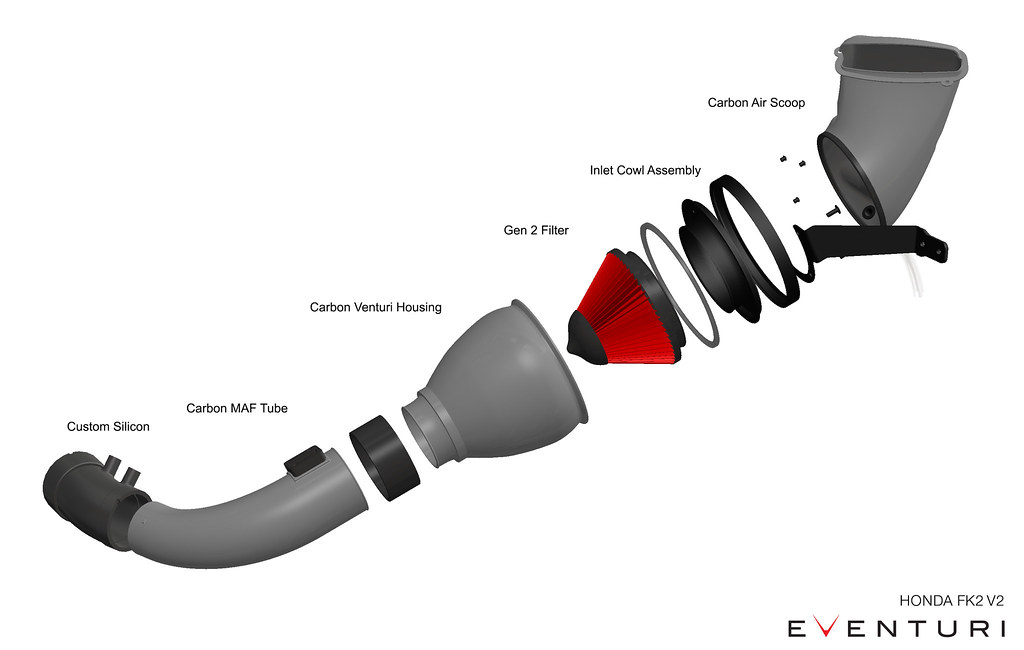

The FK2 Type R V2 intake is an updated version of our original FK2 system which now replaces the stock rubber inlet tube with our carbon tube and custom silicon hose. The new carbon tube also incorporates the MAF sensor and so also replaces our original metal MAF tube from the original Eventuri system. The addition of the carbon tube smooths the path from the Venturi filter housing all the way to the stock turbo inlet tube and the difference is significant in terms of the extra performance gained. The rest of the intake remains the same with our cold air scoop and Venturi filter housing providing smooth airflow and low intake temperatures. By integrating an effective cold air feed, which the stock system lacks and coupling that with our Patented Venturi housing and carbon inlet tube, our intake delivers industry leading results – consistently. Available in Carbon Fibre and Red Kevlar/Carbon Hybrid.

Components

Each component is engineered for a purpose and to a very high standard. Each Eventuri FK2 V2 kit consists of:

- Patented Carbon Fibre Intake Housing

- Anodised Aluminium Inlet Cowling

- Bespoke High Flow Generation 2 Filter

- Carbon Intake tube with integrated MAF Sensor Mount

- Custom Silicon Hose with Breather outlets

- Carbon Cold Air Duct with Water Drain

- OEM Windscreen Panel – Pre-Cut for the Duct

- Laser Cut Stainless Steel Mounting Bracket

- High quality Silicon coupler with OEM specification hose clamps

Carbon Intake Housing Assembly

Made from 100% prepreg carbon fibre of the highest quality, the workmanship on the housing is second to none. This encapsulates the filter and is mated to an anodised aluminum inlet cowl to ensure a smooth inlet flow path. The filter itself is a deep pleated, dry filter which has been custom made to our specification. The Venturi carbon housing smoothly shapes the airflow down to the MAF tube and ensures laminar conditions to reduce the drag on the turbo and also avoids MAF sensor errors. With the turbo able to draw air with less restriction, the engine is able to make more power.

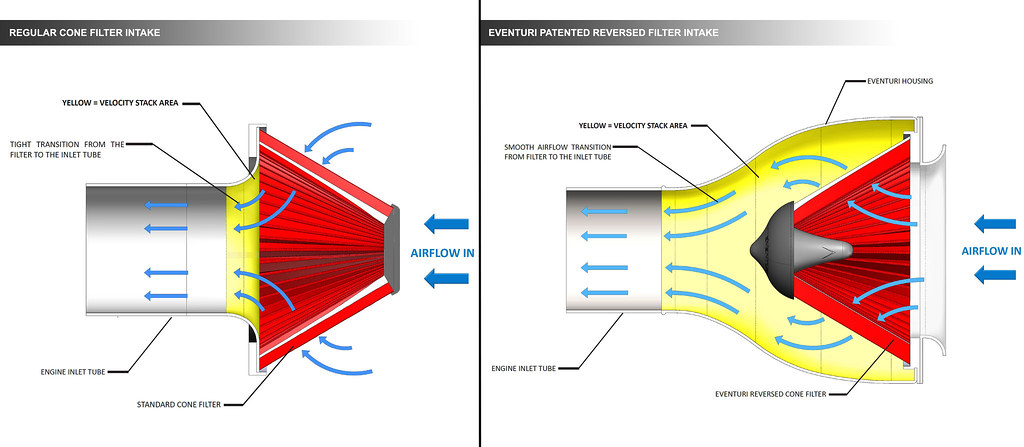

The filter housing comprises of the high flow filter, aluminium cowl, V-Band clamp, laser cut bracket and the Patented carbon pod itself. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the intake tube. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

Cold Air Duct

Shown here in red Carbon/Kevlar hybrid, the cold air duct has been designed to capture ambient air and funnel it to the filter housing. This is a key component in our system which ensures a direct and continuous feed of cold air to the filter no matter how hot the engine bay gets. The stock airbox and any other intake system without a cold air feed will suffer from heat soak and power loss as the engine bay rises in temperature. A neoprene gasket around the top lip of the duct seals it to the scuttle panel. Furthermore, there is a water drain incorporated at the base of the duct – a pvc tube is connected to this to direct water back out to the road.

Pre-Cut Scuttle Panel

For ease of installation we provide an OEM panel which has been precision cut to ensure a perfect fit for the cold air duct.

Carbon Intake Tube

Our new carbon intake tube replaces the stock rubber tube and in doing so smoothens the path from the filter housing to the turbo inlet. The carbon tube incorporates a CNC machined MAF sensor mount so there are no further interfaces after the airflow leaves the filter housing. The tube provides a more gradual change in direction from the filter to the metal turbo inlet tube as compared to the stock rubber tube – this increases the flow efficiency further. Here is a comparison between the stock and carbon tubes.

Custom Silicon Hose

The final component in our V2 FK2 system is the silicon hose which connects the carbon tube to the metal inlet tube. This part features an internal step which mates to the stock metal inlet tube and therefore eliminates the exposed wall thickness of the metal tube. Many aftermarket silicon hoses simply go over this metal tube and leave the end exposed to the oncoming airflow which results in turbulence. The photo below shows the internal step.

The carbon and silicon hoses join together to provide a much smoother path from the filter to the turbo inlet – testing showed a significant improvement in power.

The components come together to form our FK2 intake system which releases more power and torque from the engine, gives better throttle response and produces an incredible enhancement in intake sound.

Performance

The standard airbox draws in air from the engine bay which, once the engine is up to operating temperature will be very warm. Simply placing and open cone filter with any number of heat shielding in the same place will result in exactly the same problem – the system will pull in hot air and result in a loss of obtainable power. Our intake system utilises a cold air feed from the panel under the windscreen allowing the filter to be saturated with ambient air regardless of how hot the engine bay becomes. This coupled with our unique Venturi housing for smooth flow results in an immediate gain across the entire RPM range of 24-30hp and a significant torque increase of 28-35ft-lb over the stock airbox. The dyno graph shows the comparison between the Eventuri V2 Intake and the stock airbox using a stock tune and aftermarket intercooler (for all runs). As can be seen, several runs were recorded to show consistency in power gains against the standard system. The testing for each configuration was done on the same day back-to-back and temperatures were monitored to ensure consistency.

Installation Guide

Read More