Eventuri BMW M135i (F40), M235i (F44) Carbon Fibre Air Intake – EVE-F4XB48-CF-INT

Fitment: F40 M135i Xdrive, F44 M235i Xdrive, F39 X2 35iXdrive, F40 128Ti

Acceleration Time : 60-130mph Reduced By 0.2 seconds

The F40 M135i, F44 M235i Eventuri intake system was developed through extensive real world testing and airflow simulation analysis. It features our patented Venturi housing system with an integrated Mass Air Flow sensor section for the smoothest possible airflow to the turbo inlet tube. The housing encases our bespoke generation 2 dry filter which helps to shape the airflow to maintain laminar conditions. The housing seals to the front duct which has been maximised in volume to reduce any potential restrictions in flow. The duct ensures that only ambient air is provided to the filter thus IATs are steady for most driving conditions. The system allows for better throttle response and allows for the turbo to work with a lower waste-gate duty cycle.

The Eventuri Difference

The F40 M135i Eventuri system uses our Patented Carbon Fibre Housings with our Gen 2 bespoke filters, which provide an aerodynamically efficient airflow path from the filter to the turbos. Not just another cone filter with a heat shield but a unique design which invokes the Venturi affect and maintains laminar flow conditions to reduce the drag on the turbo. You can read more about the housing design and how it works

- EVE-F4XB48-CF-INT : BMW F40 M135i, F44 M235i

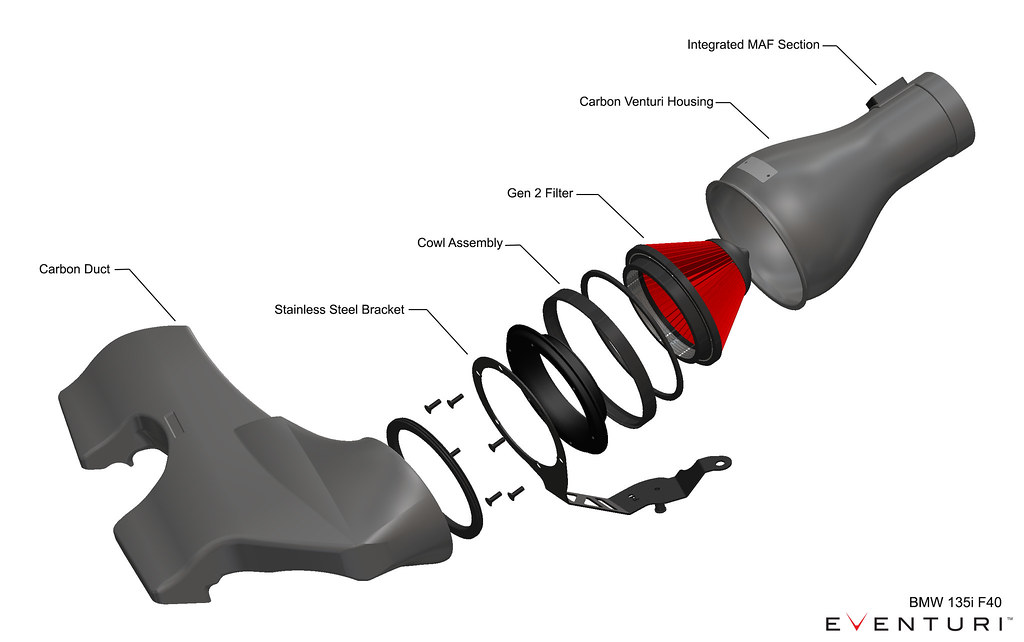

The Eventuri F40 M135i intake system consists of a number of components engineered to perform a specific purpose and fabricated to the highest of standards. Here are the details for each component and the design ethos behind them:

Each intake system consists of:

- Carbon Fiber Venturi Housing with Integrated MAF Tube

- Bespoke High Flow Generation 2 Filter

- Carbon Fiber Sealed Duct

- Aluminium Inlet Cowls

- 2 x Laser Cut Stainless Steel Bracket Work

FILTER HOUSING ASSEMBLY

The filter housing comprises of our bespoke generation 2 filter, aluminium inlet cowl, stainless steel bracket and the integrated MAF section. The carbon pod shrouds the reverse mounted filter and smoothly shapes the airflow down to the MAF section which then connects to the stock inlet tube. This changes the flow path from the OEM airbox where airflow enters the front of the airbox, changes direction by 90 degrees to travel through the panel filter and then changes direction again by 90 degrees to move through the MAF section. Our system is a lot more direct with airflow entering the front of the filter housing and and moving into the MAF section without any abrupt direction changes. The result is a smoother path from the filter to the turbo inlet tube and therefore the turbo is able to function with less drag.

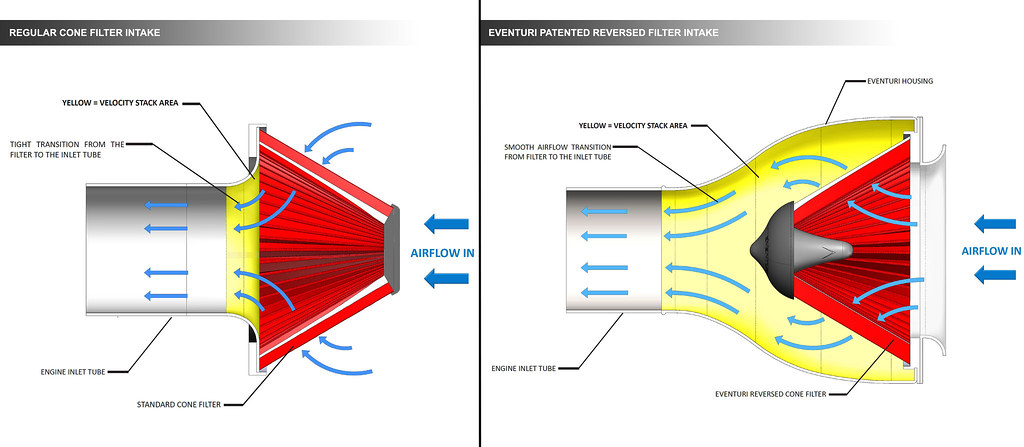

PATENTED TECHNOLOGY

Our patented filter housing has a smooth reduction in cross sectional area as it shrouds the filter and tapers down to the tubing. This geometry invokes the Venturi effect where the airflow accelerates whilst maintaining laminar conditions. It can be thought of as a large velocity stack – below is a diagram to show the comparison between our patented design and a regular intake system. Our bespoke filters aid the airflow moving through the housings and allow for an even velocity profile as the airflow exits the housings. Further details can be read in the Technology and Filters pages.

CARBON DUCT

We have redesigned the duct to maximise the internal volume. With the mounting points now hidden, the duct makes use of all the given space over the slam panel. In order to protect against engine bay heat – the duct has a flexible rubber edging around the opening to the filter housing which ensures a good seal to the filter as well as allowing movement with the engine.